MaK Engines for Offshore Petroleum Applications

At the Offshore Technology Conference (OTC) in Houston in May 2010 Caterpillar Global Petroleum announced the introduction of MaK Engines for Offshore Petroleum Applications.

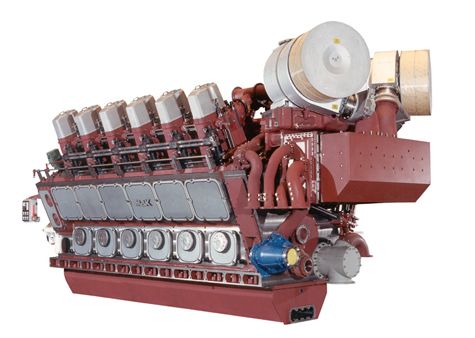

The introduction of the MaK product line for offshore petroleum applications is designed to meet critical customer requirements in the offshore petroleum industry. This line of engines has a long and successful history in the marine industry and consists of four engine families with a power output ranging from 1.020 kW at 900 rpm to 16.000 kW at 514 rpm.

The 12 and 16 cylinder M 32 C engine ratings are widely used in the offshore drilling industry and are ideal for large dynamically positioned semi-submersibles and drillships. With rated power of 5.760 and 7.680 kW at 720 rpm the M 32 C V-engines have demonstrated excellent performance and reliability in harsh marine environments where dependability is essential.

The largest family of MaK engines is the M 43 C. The 12 and 16 cylinder V-version of the M 43 C doubles the power output of the M 32 C engines to 16 mW. These engines offer higher power outputs that can serve the needs of large Floating Storage and Offloading (FPSO) vessels, multi-purpose cranes, pipelaying and drill-assist (MPV) vessels and other production units.

The MaK M 32 C and M 43 C engine families are offered as complete power systems packages. Customers have noted an increased ease in the installation process with all modules designed, built, plumbed, wired and factory tested. Major components are designed to lengthen the component life between overhauls and reduce critical customer operating costs over the lifetime of the engine.

All MaK engines meet IMO II compliance and fulfill MARPOL 73/78, Annex VI. Additional options are available to support environmentally sensitive areas with smokeless operations. This strategy exemplifies inside-the-engine solutions, without resorting to external exhaust emission aftertreatment. The MaK emission solution offers a clear advantage in the industry and will be favored by design engineers and HSSE alike with respect to cost, complexity and maintenance.

All MaK engines have a proven history of reliability, durability and low operating costs, and are being build in Kiel and Rostock in Germany as well as Shunde in China.

We use cookies to improve your experience. By continuing to use our site, you accept our Cookies, Privacy Policy,Terms and Conditions. Close X